Product Details

Category

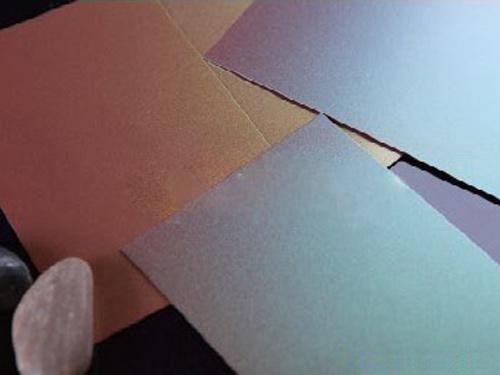

Nano+PVDF Coating Aluminium Composite Panel

VICOBOND is ISO9001:2000 quality system management certified manufacturer of high quality aluminium composite panel,aluminium cladding sheet in China. We import 20 advanced multi-functional fully automatic controlled equipments with highest Germany technology,including coating line,compositing line,aluminium sheet production line ect.

Category:

Aluminum plastic composite board (also known as aluminum plastic board), as a new type of decorative material, was introduced from Germany to China in the late 1980s and early 1990s. With its economy, diversity of colors available, convenient construction methods, excellent processing performance, excellent fire resistance, and noble quality, it has quickly gained people's favor. The unique performance of aluminum plastic composite panels determines their widespread use: they can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decoration, advertising signs, display stands, and purification and dust prevention engineering. It belongs to a new type of building decoration material.

|

ltem |

Aluontop Result |

AAMA2605-05Requirement |

|

Dry film scratch hardness |

F |

Minimum F (No rupture of film) |

|

Dry adhesion |

No removal of film |

No removal of film |

|

Wet adhesion |

No blistering |

No blistering |

|

Boiling water adhesion |

No blistering |

No blistering |

|

Impact resistance |

No removal of film |

No removal of film |

|

Abrasion coefficient (litres/mil) |

|

40 minimum |

|

Muriatic acid resistance10% (v/v)HCL |

No blistering |

No blistering |

|

Mortar resistance |

Mortar dislodged easily |

Mortar shall dislodge easily |

|

Nitric acid£(70% w/w) resistance, |

1.3 |

Not more than 5△E units (Hunter) |

|

Detergent resistance |

No loss of film adhesion |

No loss of film adhesion |

|

Window cleaner resistance |

No remove of film under tape |

No remove of film under tape |

Keywords: Nano+PVDF Coating Aluminium Composite Panel

Recommended Products

sales@vicobond.com

sales@vicobond.com

0086-17511642571

0086-17511642571 中文版

中文版 English

English Español

Español